Southern Pacific

9010

Bits And Pieces

Restoration of any

locomotive is a

complex, time-consuming process. Restoration of a locomotive built

nearly 6,000 miles from where you keep your toolbox is that much harder!Bits And Pieces

This website has acted like a 'volunteer magnet' for the SP 9010 project, bringing together people, parts and expertise from California to Bavaria and points in between.

Part of the fun of restoring the KM has been the unique challenges of restoring a railroad artifact with 'foreign content' to a credible level of accuracy. It was a surprise to discover how much U.S.-style content is actually there; all threads and fasteners except for those on European-sourced components are usually SAE standard. Sheet metal dimensions, though, are metric, and if there's a question about a dimension, it usually works to go up or down to the nearest 'round' metric equivalent.

But there are some parts that are 'custom' to the Krauss-Maffei heritage, and for those we've relied on international cooperation!

We'll keep updating this page as we source more interesting bits and pieces.

CAB ASHTRAYS

Like the TV show "Mad Men", there was a lot of smoking on the job in the 1960's! Builder's photos of the KM cabs showed three jewel-like chromed ashtrays -- one at the Fireman's left hand, one on the forward bulkhead/heater console, and one tucked under the Engineer's desk.

Krauss-Maffei AG

|

Krauss-Maffei AG

|

Krauss-Maffei AG

|

We used 'Google' to search the obvious choices with little luck, until a conversation with our German friends led us to the likely source. Krauss-Maffei built intercity buses until right around the time of our ML 4000 locomotives, and each seat had an ashtray on the facing seat back. KM likely reached into that parts bin for the locomotives.

A patient daily search on eBay.de turned up three ashtrays over the span of about five months in 2009 -- one in flawless unused condition, one in very good condition with a little wear, and one in used shape and a little rusty, but with an original 'KM' logo!

Bob Zenk Photo

|

Richard G. Oed Photo

|

Bob Zenk Photo

|

We'll be making the logos for all three, since the factory photos show a light-colored logo, and the one 'aschenbecher' we have with logo has a black imprint. We're also going to use security hardware to mount them, since of the 63 factory ashtrays installed in the 21 KM locomotives, we've never seen one turn up, and suspect they were MIA within the first few weeks of service, if not the first few days!

Thanks to Richard G. Oed for being our go-between, benefactor, and postal service!

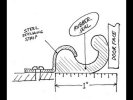

RUBBER SEALS

The hood structures and cab are all separated and isolated by an H-section continuous gasket. (In fact, the entire cab is mounted on rubber isolators.) On SP 9010, these seals are either hard as a rock and crumbling, or missing entirely.

David Thelen Photo

|

Bob Zenk Photo

|

Bob Zenk Photo

|

There was no commercial part available in the U.S. which could have done the job, and this is one of the most distinctive and functional details of the KM's construction. We contracted with a company in Oregon which specializes in short-run custom rubber. Without original KM drawings at the time, we supplied the original cross-section and the optimum dimensions, and they supplied 125 feet of beautiful and long-lasting neoprene.

Bob Zenk Photo Bob Zenk Photo

|

Bob Zenk Photo

|

The part fits like a glove. About a month later, the missing drawings came into our hands. Turns out we'd done a perfect job without them. Thanks to Denny Mann for taking up this commission!

We'll likely use the same avenue to create the special seals for the cab doors, unless we can find a U.S.-sourced material that matches.

Bob Zenk Photo

|

Bob Zenk

|

Dave Maffei Photo

|

CAB UPHOLSTERY

The 'sport seating' cab chairs are extremely comfortable, ergonomic, and multi-adjustable. They were built by Bremshey & Co., now one of Germany's leading exercise machine manufacturers. They feature a gas-strut suspension (adjustable for height and weight), a backrest with lumbar support and four angles of rake, a seat cushion also rake-adjustable, swivel locks, fore-and-aft sliding adjustment, and movable armrests.

Krauss-Maffei AG

|

David Thelen Photo

|

We're lucky to have the originals and a couple spares, since the Camera Car conversion used two extra ML 4000 seats for the camera and audio operator's positions. (We're especially lucky to have a full house complement, since the word was out among SP employees when the KM's went to scrap that the seats made great seats for your bass boat!)

Howard P. Wise Photo

|

The only issue is that Sacramento General Shops did a reupholster in the late 1960's, and the original fabric was replaced. This fabric had an unusual 'crush grain' pattern, and was set off with black welt-cord piping -- material which also carried over to the inside and outside cab armrests, both missing on SP 9010.

Krauss-Maffei AG

|

A search in the U.S. of all auto, industrial, truck and bus, and marine vintage and contemporary upholstery turned up nothing of even remote similarity. And the search is complicated because Germany has been on the leading edge of 'green manufacturing' for years, and vinyl-making is a particularly dirty business, or can be. We were uncertain if we'd ever be able to reproduce the fabric.

Enter our friends in Germany once again, who found a source for this fabric with a restaurant supplier of vintage upholstery materials. So far, we know they make the same fabric in red, and are crossing our fingers that we can get a sufficient amount of yardage ('meterage'?) in green.

Bob Zenk Photo

|

TOOLS

We heard that one of the former Roseville KM shop techs might have a line on a set of Dowidat metric tools used on the dedicated shop track for the KM 'hydros'. He did, and now they're with the locomotive! (The end wrenches look exactly like the tools in a cloth bag in the trunk of every 1960's Mercedes-Benz. The same manufacturer made both.)

Mike Myers Collection

|

NUMBERBOARD LATCHES

These little beauties are one of the most distinctive things on the nose of the 'Series' KM. They deserve proper reproduction -- but of the parts saved by Bob Zenk in 1969, there were only three. We need six total. Our new-found eBay.de skills have so far turned up nothing. Richard Oed believes that these parts were made by KM apprentices specifically for the locomotive, and close inspection reveals them to be a very handmade-looking part indeed, with some tolerances down to the microns, and others looking roughly hand-filed.

Krauss-Maffei AG

|

Bob Zenk Photo

|

Bob Zenk Photo

|

One of our friends in Southern California is computing the dimensions towards making a casting pattern. While we pursue this avenue, we've also got our eye on a marine fitting which will look very close from the ground and will do the same job. We might use those for the time being, until we can make perfect replacements.

These latches (and the whole mounting of the numberboards with easy access at chest-height) were among the best-thought-out accommodations for SP's practice of changing train and engine numbers. The practice ended in 1967 except for commute trains. The idea of KM's in commute service is one that some of us can't let go of, and what a perfect service this might have been - for those chrome latches, anyway!

The original KM specs called for numberboards front and rear, by the way. Maybe we should make twelve latches?

Richard G. Oed Collection

|

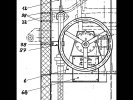

CAB GAUGES

The back panel had indicators for both Maybach V-16 motors and both Voith transmissions, and showed engine RPM and hours, as well as temperatures for cooling water (turbo aftercooler), engine lube oil (in), engine cooling water (in and out) and transmission oil (out).

Krauss-Maffei AG

|

SP apparently felt that either this was too much information, too many senders to maintain, or too many wires to connect and disconnect during service, because the temp 'in' gauges and engine hour counters were removed and blanked while in locomotive service. The Camera Car conversion eliminated the rest, and vandals destroyed what was left of brake pipe and hydrodynamic brake gauges on the 'driver's desk'.

|

|

The brake system gauges won't be hard. But the rest are uniquely European. After working with our friends in the KM family and at Maybach's successor MTU, we've determined that the large gauges were manufactured by DEUTA (still in business) and the smaller gauges likely were made by Hartmann & Braun (now part of the ABB Group).

We have a line on both, looking for non-working or working gauges which might suffice to get the panel looking good again. Nothing yet, but we're still tracking down leads, including an offer by DEUTA people to search their shelves.

NOSE VENTS

There are two pop-up vents on the top of the nose, to ventilate the forward transmission compartment. These parts are identical to the rooftop vent over the 'Water Closet', which is still in place on SP 9010.

Howard P. Wise 2008

|

Krauss-Maffei A.G.

|

David Thelen 1964

|

We puzzled over how best to create two replicas of this one part -- a complicated task even to create a non-working 'fake'. That's when one of our Crew noticed that the rooftop of an HO scale Krauss-Maffei V300 locomotive model features not one, not two... but twenty of these vents! There is no V300 any longer (it was scrapped by 1980), but there are a goodly number of similar locomotives sitting on salvage tracks in Europe, with some being rebuilt for many more years of service.

Richard G. Oed

|

Surely there must be refurbished or salvage parts available for these projects?

We quickly contacted our European team of 'volunteer sleuths', and within a relatively short amount of time were anticipating shipment of one pair of original 1950-60 era vents in used condition (courtesy of a locomotive rebuilding company), and one brand-new pair of replacement parts (courtesy of an associate of the German railways).

Richard G. Oed

|

Gerold Eckl

|

Richard G. Oed

|

The new pieces have a couple slight variations from the originals, so the best combination of authentic pieces to exactly replicate SP 9010's vents will be used. The plan is to make them functional for appearance's sake, not a contradiction when thinking about the 'life' they'll add to the new nose. They're authentic German parts, they're the last items to be attached to the re-created short hood, and will save countless hours of fabrication. The power of networking!

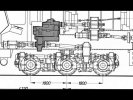

SPARE TRUCKS. (SPARE TRUCKS??)

SP 9010 has no way to move on its own, because all its infamous gearboxes were removed and destroyed forty years ago. We've looked at other KM hydraulics around the world, and found no exactly-suitable equivalents. The U.S. spec boxes were more rugged to accommodate the high USA horsepower and sustained loadings, and the gearboxes in fact were redesigned and refitted to the 'Final Four' units including ours.

The best way to provide for a distant future in which the 9010 could be powered by her rear Maybach and Voith transmission (for our grand children's grandchildren?) would be to find an original set of SP-spec gearboxes and axles. Impossible, we thought. One look at the current state of the 9010's final drive is all it takes to want to throw in the towel:

|

Yet Otto Baumgartner recalled gondolas filled with KM trucks leaving the Associated Metals scrapyard intact. He remembered that these trucks had been purchased for re-use by Plasser & Theurer, the Austrian manufacturer of track and roadbed maintenance equipment used worldwide.

A call from SP 9010 friends in Austria to Plasser & Theurer was cordially received, but they hadn't kept records and couldn't say. Then, Richard Oed obtained a Voith catalogue listing Voith transmissions and drivetrains supplied in the 1960's and 1970's. And there, plain as could be, was the profile in cutaway of the ML 4000 Series truck!

Plasser & Theurer constructed model RM63 ballast-cleaning units between 1970 and 1975, using former SP ML4000 trucks in combination with a 520kW diesel and Voith transmissions. Three RM63 units were built for Deutsche Bundesbahn: one in 1970 and two in 1972. One of these units was sold to a private company in the 1990s and may still be serviceable. One unit was built for a private Geman firm, Wiebe, in 1975 but may have been equipped from the factory with Henschel-made trucks. And one RM63 was was built in 1970 for a French rail construction company, SECO/Desquenne et Giral -- and may still be operational.

Richard G. Oed Photo

|

Richard G. Oed Collection

|

Do we have our spare trucks and gearboxes? Not yet. The RM63 trail leads at a rebuilding to "RM630" configuration in the 1990's. Photos of those units do not show KM-style trucks, sadly. Could some have been saved?

We're still looking...

Windshield Wiper Arms

Sometimes it's easy. In the case of 9010's air-operated equipment, most was supplied by U.S. manufacturers and 'reverse imported' for assembly. Such was the case with the Air Push windshield wiper assemblies. Sprague Devices still catalogs the parts, though in this case the classic silver arms and blades are being discontinued in favor of black. We got two for 9010 before this happened.

Brand-new parts, from current stock, for a 46-year-old stranger in a strange land. Pretty good!

|

Original Handbrake Wheel

The KM factory used customary German design on the ML4000 handbrake application -- a cab-mounted wheel with folding handle, and a chain drive to an expanding double-action worm gear, acting on the brake rigging of the front truck, fireman's side.

We heard a funny story from one of the former Roseville techs: apparently the only people who claimed the job of maneuvering inside the cramped area to lubricate the exposed chain and gears and check the associated U-joints and boots were the young guys. Actually, the young, low-seniority guys. And actually, the one guy we spoke to said he was the only guy who was skinny enough to climb in there and do the job. It was certain no one else wanted to do it!

SP eventually applied a more traditional U.S. brakestand to the engineer's side front walkway. This in turn was removed when the new camera nose was fabricated, and reinstalled on the fireman's side rear walkway.

That location probably will be renewed. (See "SP's Modifications") But for pure cosmetic fun and to return the cab to original 1964 appearance as much as possible, we were able to secure the correct brake wheel from our good friend Franz Wunschik in Germany. It will be non-functional -- but that won't stop us from suggesting to visitors that it actually works the dive planes when submerging!

Bob

Zenk Photo

|

Krauss

Maffei AG

|

Krauss-Maffei AG

|

Krauss-Maffei AG

|

Cab Flooring

The original floor in the cab is a brick-red marbleized rubber. It's chipped or missing in many places, and in need of complete replacement if the quality of restoration is to be maintained. We couldn't find the specifications for the material KM used, but did find an OEM (Original Equipment Manufacturer) in the U.S. -- RCA Rubber -- who provided us with a roll of what is essentially an exact replacement, and it's possible they were the original supplier. No resorting to box store square tiles for 9010 -- we now have the real deal. Installation will be the last step in the cab refurbishment process, once all the nasty work is complete.

One note: make sure you don't allow wires to cross between the billing department and the shipping department -- or be sure you can tap a cousin to help you wrestle 135 pounds of dead-weight rubber off your front porch where the UPS guy left it!

|

Bob

Zenk Photo

|

Bob

Zenk Photo

|

|

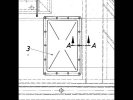

Cab Door Seals

The cab doors shut as solidly and confidently as the doors on a Mercedes-Benz. KM used a double row of rubber weatherseals, but not strictly for sealing against weather -- the double row was part of the sound isolation system which included rubber mounting cones for the cab structure itself, thick "Stone Wool" insulation behind perforated cab inner sheet metal lined with fiberglass cloth, and dense sprayed-on urethane sound absorbing coatings on the insides and reverse faces of hood doors.

The seals are a custom shape, and held in with a rolled keeper strip. As we've discovered with many items on the KM, these are parts which have found widespread use in the German railway system, and are still being stocked for refurbishment and repair. An inquiry to our "German Lifeline Team" of volunteers resulted in enough of this material, brand new, to replace all the rubber on the two rear cab doors, plus install it new on the Fireman's side door that we are in the process of fabricating. Thanks goes to our facilitating friend Richard Oed, and to his generous sources in Germany. It appears that the 9010 restoration has fans in many places.

Bob

Zenk Photo

|

Krauss-Maffei AG

|

Richard

G. Oed Photo

|

Richard

G. Oed Photo

|