Southern

Pacific 9010

Mechanical Work

Page 4

Page 4

-- Update December 13, 2016 --

Injectors!! This project has been at the top of our need-to-do list for quite some time and we recently were offered a set of rebuilt injectors from the Diesel Traction Group in the UK (http://www.westernchampion.co.uk/) at a reasonable price. We were forced to replace our injectors because the originals were stuck from the years of sitting.

Ordering and paying for the replacements was very simple but getting them to the US proved to be quite a struggle. Our crew member Rob made a 400 mile round trip from Plymouth to pick them up, carefully boxed them and arranged for shipment through UPS. Rob packaged the injectors and some spare parts in 5 boxes so that each box would weigh under 50 pounds and not be too hard to handle. Good old UPS managed to get 2 of the boxes delivered but 3 of them were rejected in the UK and not only were we not told why but we could not get a refund on the shipping! Three of the boxes were returned to Rob who repackaged them and put one back in UPS. This box sailed right through the system but we decided to try Fedex for the other two deliveries. Fedex was superb and I had the two boxes as scheduled.

|

|

|

|

The injector is almost like a kit.

The parts are installed in a specific order in

order to clamp it into the head and adjust the fuel flow.

Installing the injectors is unlike anything found on domestic US engines. The process requires a number of very special Maybach tools, a lot of patience and a fair amount of time. Here follows a few photos of the installation.

Installing the injectors is unlike anything found on domestic US engines. The process requires a number of very special Maybach tools, a lot of patience and a fair amount of time. Here follows a few photos of the installation.

|

|

|

|

Part

of the injector installation requires that the crankshaft be carefully

barred over to a specific spot for each injector. This was

much

easier to do without the #1 cardan shaft in place but requires two

people, one to watch the degree wheel on the crankshaft and the other

to bar the engine. With everyone busy on other projects, I

decided to let technology be my helper. A video camera was

focused on the degree indicator and its output was connected to a small

DVD player. I could now bar the engine and see the crankshaft

position. The dial

indicator is used to adjust the screw on the end of the injector rocker

arm and thus the injection timing. With all the injectors

timed,

the cam box cover frames and fuel lines could go back on.

|

|

|

|

Once the

injectors were in and timed, we installed the last of the new cardan

shafts from The Welte-Group in Germany. We owe a great deal

to Mr. Egon Welte for his help with the project. Dennis and

Rich muscled the 975 pound shaft while I supervised and ran the fork

lift. Still to

come are torquing the bolts and installing the shaft's safety straps.

The shaft and couplings will eventually be

completely covered to conform to FRA regulations.

|

|

|

|

|

|

|

|

|

|

|

|

|

--

Update December 30, 2016 --

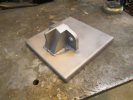

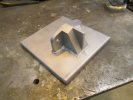

After torquing the coupling bolts, the next operation on the cardan shaft was the installation of the safety straps. These were made from 3/4" thick steel and formed by our friends at Melrose Metals. At some point in the future, a cage will be made that will duplicate the one that was there originally.

After torquing the coupling bolts, the next operation on the cardan shaft was the installation of the safety straps. These were made from 3/4" thick steel and formed by our friends at Melrose Metals. At some point in the future, a cage will be made that will duplicate the one that was there originally.

|

|

|

|

For our final effort in the 2016 year, we ran the engine over using the power of the dynastarter. The fuel pump was running as was the pre-heater and the compression relief valves were open. It was a payment to ourselves for the hundreds of hours of preparation work that preceded this moment. An attempt to start the engine is not too far in the future. The following video is courtesy of the editing skills of Bob Zenk.

-- Update February 03, 2017 --

When we received the locomotive, the fuel gauge on the right side of the tank indicated about 1800 gallons while the one on the left was unreadable because the fuel had leaked into the gauge face. The gauge on the right was an EMD component so we bought an identical gauge for the left. We knew that the fuel had been in the tank since at least 1980 so decided to empty the tank and start fresh. Once the tank was empty, the gauge on the right still indicated 1400 gallons! Once removed, the gauge level arm proved to be about 6" too long and was trapped by a tank baffle. The second photo was taken looking through the hole for the right hand gauge and looks across the tank. The pipes seen are the suction lines for the engines and engine pre-heaters. The 9010 now has two functional fuel gauges on the tank.

|

|

FRA regulations require that

rotating apparatus

be covered to protect employees. The resilient coupling and

#1

cardan shaft (rear engine) fall under this requirement. There

was

one half of the coupling cover left on the rear engine and the same

half remained on the front engine. The half cover from the

front

engine was modified to become the left side for the rear coupling.

Design is progressing for the cardan shaft cover.

On January 17th, we attempted to start the rear engine. We have an old, used set of batteries in the 9010 so we used jumper cables to access the batteries on another locomotive. We were not successful, mainly because of the discovery of a very defective exhaust elbow on the rear turbocharger. There is a short video of the event on Youtube at: Maybach start, first attempt.

The video comments give more information about the trial. After removing the elbow, the rear turbo was found to be frozen so we had to deal with that. The elbow was repaired and another start attempt will take place soon. The metal is quite brittle so was very difficult to weld. I hope the welds hold! If not, we will be digging into the front engine for a replacement.

|

|

|

|

|

|

|

|

--

Update February 18, 2017 --

On February 14, 2017 we tried for the second time to start the rear engine. This time was much more successful! There is a video of the start on Youtube at Maybach start, second attempt. We were amazed at how smoothly the engine ran after being dormant for nearly 50 years.

On February 14, 2017 we tried for the second time to start the rear engine. This time was much more successful! There is a video of the start on Youtube at Maybach start, second attempt. We were amazed at how smoothly the engine ran after being dormant for nearly 50 years.

|

--

Update June 21, 2017 --

Prior to starting the engine, the new cardan shaft cover was completed and installed. The removable panels at the front and rear are for access to the grease zerks on the universal joints and the sliding coupling.

Now that we have a running engine and a seemingly functional transmission, the specter of our empty cooling hood again rears it ugly head. We have been discussing this issue for several years, with many ideas both reasonable and far-fetched on the table. The hood is divided into 6 sections, 3 on each side with 6 cooling elements in each section. The first 4 elements on each side (right of photo) are dedicated to the turbocharger aftercooler cooling and the rest of the 24 elements are for everything else.

Bill came up with the brilliant idea of taking an original radiator element to a local shop to see if there was something they could do. At the shop, Jim removed the torn up radiator from the ends and figured out how to attach a new core to the ends. We had 6 original elements from which we could build 6 new units. We decided that these would be mounted in the right front hood section and this would be our "display bay," showing what the original cooling system looked like. What would happen to the rest of the hood was, as I mentioned, open to debate.

It wasn't until our friend and crew member Lorenzo Pantani in Italy came up with plans for cooling element ends to be made on a computer controlled milling machine that we realized we could create elements that would fit like the originals and give us full cooling capacity. With a very generous donation from major project supporters Dick and Barbara Harley and the agreement of the PLA Board Of Directors, we decided to proceed with the venture.

Each end consists of 3 pieces. The "pan" will be soldered to the end of the new core. The "collar" will be attached to the "neck" which in turn will be welded to the pan. The collars (which Bill designed) could have been included in the CNC milling but it was by far cheaper to produce them ourselves from DOM tubing, turn them on our lathe and press them into the neck. During welding, the collar was tack welded to the neck inside the necks hole. Producing 60 of these assemblies took quite a bit of time but the results will be worth the effort. There will be photos of the radiator elements when we receive some of them from the shop.

Prior to starting the engine, the new cardan shaft cover was completed and installed. The removable panels at the front and rear are for access to the grease zerks on the universal joints and the sliding coupling.

Now that we have a running engine and a seemingly functional transmission, the specter of our empty cooling hood again rears it ugly head. We have been discussing this issue for several years, with many ideas both reasonable and far-fetched on the table. The hood is divided into 6 sections, 3 on each side with 6 cooling elements in each section. The first 4 elements on each side (right of photo) are dedicated to the turbocharger aftercooler cooling and the rest of the 24 elements are for everything else.

Bill came up with the brilliant idea of taking an original radiator element to a local shop to see if there was something they could do. At the shop, Jim removed the torn up radiator from the ends and figured out how to attach a new core to the ends. We had 6 original elements from which we could build 6 new units. We decided that these would be mounted in the right front hood section and this would be our "display bay," showing what the original cooling system looked like. What would happen to the rest of the hood was, as I mentioned, open to debate.

It wasn't until our friend and crew member Lorenzo Pantani in Italy came up with plans for cooling element ends to be made on a computer controlled milling machine that we realized we could create elements that would fit like the originals and give us full cooling capacity. With a very generous donation from major project supporters Dick and Barbara Harley and the agreement of the PLA Board Of Directors, we decided to proceed with the venture.

Each end consists of 3 pieces. The "pan" will be soldered to the end of the new core. The "collar" will be attached to the "neck" which in turn will be welded to the pan. The collars (which Bill designed) could have been included in the CNC milling but it was by far cheaper to produce them ourselves from DOM tubing, turn them on our lathe and press them into the neck. During welding, the collar was tack welded to the neck inside the necks hole. Producing 60 of these assemblies took quite a bit of time but the results will be worth the effort. There will be photos of the radiator elements when we receive some of them from the shop.

We have also began the process of

pressure testing the cooling hood. Back in 2010

when the cosmetic restoration of the hood was done, no thought was

given to a functional cooling system. Times have obviously

changed and we need to make sure that nothing leaks. All of

the water connections for the missing radiator elements have been

capped and all

pipe flanges and other connections closed off. The system

will be

filled with water and pressurized to about 25 pounds per square inch.

The radiator pressure caps are set at 15 psi so the 25 psi

will

give us a bit of extra insurance. There will be more about

this

in a future post.

|

|

|

--

Update August 26, 2017 --

Our buddy and 9010 project Minister of Information Bob Zenk came down from Seattle this month. His aim was to apply some of the frame lettering to the 9010 and he succeeded admirably. It is a rather tedious process but the "stencils" created by PLA member Chris Hauf were beautiful and I enjoyed applying paint over them. By the way, the lettering is in the "DIN 1451" font which is the German standard typeface as applied to other German locomotives. Bob also developed the stencil artwork, and determined correct positioning with his iMac, using detailed photos taken by David Thelen in 1964 and provided to us by David's brother Lou. The paint is PPG catalyzed urethane Southern Pacific Lettering Gray as custom mixed by our paint supplier, San Leandro Color. Dennis and I took some time to stand and admire the work.

Our buddy and 9010 project Minister of Information Bob Zenk came down from Seattle this month. His aim was to apply some of the frame lettering to the 9010 and he succeeded admirably. It is a rather tedious process but the "stencils" created by PLA member Chris Hauf were beautiful and I enjoyed applying paint over them. By the way, the lettering is in the "DIN 1451" font which is the German standard typeface as applied to other German locomotives. Bob also developed the stencil artwork, and determined correct positioning with his iMac, using detailed photos taken by David Thelen in 1964 and provided to us by David's brother Lou. The paint is PPG catalyzed urethane Southern Pacific Lettering Gray as custom mixed by our paint supplier, San Leandro Color. Dennis and I took some time to stand and admire the work.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

--

Update December 24, 2017 --

It has been nearly 4 months since the last update but work has continued. Bob does such an excellent job with our Facebook page that I tend to ignore the web site. So, let's consider this a year-end update and I will try for more frequent updates next year.

The big news is that the 9010 moved under her own power. Gerry was the first to notch out the throttle and feel the transmission put power to the rails. Of course, we cannot run the Maybach for very long because our cooling is limited to the water in the engine block but having her move was a thrill. In October Rob came over from the UK and we ran her again until the water temperature told us to shut down the engine. There is a short video of Rob running the locomotive on Youtube here. The smile on his face tells the tale.

We purchased a full set (8) of new batteries and are now able to start the engine without the aid of jumper cables. Our cranking speed went up from around 75 RPM to a bit over 200 RPM which makes all the difference in the world. The batteries we had in the 9010 were a used set that had been removed from our 80-ton GE because they were worn out. They served our purpose for a while but the time came to send them to the scrapper.

The hydraulic pump system is somewhat more complex than the compressor installation. There are two pumps because there are two separate cooling fan circuits and we were given a pump from a piece of dirt moving equipment. This pump had 3 sections so one was removed making the dual pump we need. We also got parts including a pump mount and oil tank from a piece of track maintenance equipment.

Return

To Main PageIt has been nearly 4 months since the last update but work has continued. Bob does such an excellent job with our Facebook page that I tend to ignore the web site. So, let's consider this a year-end update and I will try for more frequent updates next year.

The big news is that the 9010 moved under her own power. Gerry was the first to notch out the throttle and feel the transmission put power to the rails. Of course, we cannot run the Maybach for very long because our cooling is limited to the water in the engine block but having her move was a thrill. In October Rob came over from the UK and we ran her again until the water temperature told us to shut down the engine. There is a short video of Rob running the locomotive on Youtube here. The smile on his face tells the tale.

We purchased a full set (8) of new batteries and are now able to start the engine without the aid of jumper cables. Our cranking speed went up from around 75 RPM to a bit over 200 RPM which makes all the difference in the world. The batteries we had in the 9010 were a used set that had been removed from our 80-ton GE because they were worn out. They served our purpose for a while but the time came to send them to the scrapper.

|

|

|

Cooling

system reconstruction is well over 50% completed. As of

today's

date, we need only 11 more radiator cores. The quality of the

work we are getting from Centerville Radiator is outstanding.

After installing 1 or 2 cores, we pressurize the system to 25

PSI

and have had absolutely no leaks. While Rob was here from the

UK,

he put himself to work finish grinding the last of the end caps and

Dave was caught painting a couple of the new cores.

|

|

|

The locomotive was originally

equipped with a Barco repeating speedometer on the engineers desk.

It was long gone and no exact replacement could be found so

an

electronic unit was adapted. It was necessary to calibrate

the

unit to our speed sending units and the first 2 photos reflect this

process. The variac is providing fine control to the battery

charger which in turn is powering a 32 volt motor which is connected to

the GE axle drive. It was all a bit Rube Goldberg-ish but it

worked just fine. A low frequency pulse generator could be

used

for the same purpose. Some bits and pieces were finally

painted

and Bob installed them in the cab along with the Happich sun visors (sourced by

Richard Oed in Germany) and the brand new position indicators made by

Seattle Engraving.

|

|

|

|

|

|

Two of the systems we still do not

have are a compressed air supply and a supply for the hydraulic system.

The parts for both are 100% missing thanks to the Camera Car

conversion in 1968. We are trying to maintain historic

accuracy on the visible aspects of the locomotive but for the air and

hydraulics, we are left to be creative. We actually only need

a compressor and the means to drive it for the air supply.

Thanks to our good friend Matt Monson of Diesel Motive, we

now have a locomotive style compressor. It is somewhat

smaller than the original unit but should suffice for the reasonably

low demands of the 9010. The only complex part of this

project was the modification of some existing parts to create the

needed belt drive and coupling to the engine crankshaft.

|

|

|

|

|

|

The hydraulic pump system is somewhat more complex than the compressor installation. There are two pumps because there are two separate cooling fan circuits and we were given a pump from a piece of dirt moving equipment. This pump had 3 sections so one was removed making the dual pump we need. We also got parts including a pump mount and oil tank from a piece of track maintenance equipment.

|

|

|

|

We also acquired a new volunteer.

Her name is Dee and she is an absolute terror with a needle

gun! She has taken on the task of cleaning all of the areas

behind the frame doors and re-installing the friction dampers.

There will be more about this as her work progresses.

|

|