Southern

Pacific

9010

Modifications 1964-68

Modifications 1964-68

~ Robert J. Zenk

Appearance Through The Years

1964

Gordon Glattenberg |

1965

Jack Whitmeyer |

1966

Carl-Peter Zander Collection |

1967-68

Don Douglas |

Just the facts. And a little speculation.

On this page is what we know so far -- including some good guesses -- about the visible and internal changes to SP 9010 over its four-year lifetime in locomotive service. And here we stress 'so far', since new information has been surfacing at a remarkable pace, largely due to SP 9010's blossoming internet presence and growing international fan base!

SP 9010: the rarest bird.

Thanks to photographers Otto Baumgartner, Don Douglas, Gordon Glattenberg, Richard Oed, and Jack Whitmeyer, we have some striking images of our locomotive operating while numbered '9010', a period lasting perhaps 23 months at most. For some reason, SP 9010 evaded cameras more than several of its siblings.

SP 9113: a more frequent flyer.

Physically renumbered as SP 9113 in early 1966, the locomotive was captured on film a little more often as photographers realized that the days of the 'Hydros' were numbered. But the overall photo record of our artifact is still spotty, and images of either 9010 or 9113 are a rare treasure.

Writing the history of a machine.

It's our goal to completely document every significant modification received by SP 9010 through its service life on the Southern Pacific Railroad. This is a forensic process, and to determine the 'mods history' we're using a simple technique: searching for every last thing we can get our hands on!

Every detail tells a story.

The artifact itself is, of course, our first source of reference. We keep finding new and curious details and trace evidence, and expect we'll continue to do so. These locomotives were constantly having fresh 'remedies' applied, and no two of the 15 Series units were exactly alike once the SP and KM put their heads together (or butted them) to solve problems.

Period notes and contemporary research.

Next comes the treasure trove of new info provided through the detailed notes and crisp recollections of former KM maintenance personnel including Otto Baumgartner, Carl-Peter Zander, and other KM and SP Roseville Diesel Shop veterans. There's also the deep research being done by Richard G. Oed, son of Richard Oed who was the ML4000 Project Lead Engineer for Krauss-Maffei.

Also to be highly credited are Franz Wunschik, Gerold Eckl, Mathias Fetscher, and Rob Fern, who continue to assist from across the ocean with liaison, deep research, expertise and advice. From the USA perspective, we're indebted to the PLA's Jim Evans and his collection of the photos of Joe Ward, and to the recollections of our KM engine and service crews: Errol Ohman, Dan Ranger, Charlie Heimerdinger, Tom Irion, Chuck Drake, Gene Corral, and Jim Wagner.

A picture is worth 9010 words.

Complementing this information in value are the rare photographic records of SP 9010, anecdotal recollection and various personal collections of memorabilia and writings, and finally the photos we have on hand from the 14 other members of the ML4000 'Series' fleet. Special thanks here go to Lou Thelen, who shares with us a fantastic set of "walkaround" detail photos taken by his brother David in 1964 -- and proving invaluable to the reconstruction of SP 9010 (see "Memories").

SP 9010 MODIFICATIONS: THE LIST

1965,

Bayshore, Ca.

Richard

G. Oed Collection

|

Modifications to SP 9010 are listed in roughly chronological order, as near as we can determine. For some, we have detailed notes. For others, it's just our collective best guess at the moment. But this page will change and grow as new information is uncovered.

Case in point: 'changes' keep changing.

Those who regularly study this page will note that we've removed some items from the 'SP Modifications category', after determining that the modifications in fact were made by Krauss-Maffei before the unit was shipped.

Items we now believe to be KM factory mods are:

RAISED EXHAUST UPTAKES

Original production called for a recessed exhaust, common to KM designs in Germany, and fitted to the six Prototypes and the first seven Series units, 9003-9009.

Presumably as a result of 'breathing' problems experienced by the six Prototypes in long U.S. tunnels at slow speeds, Maybach supplied KM with taller exhaust uptake castings for the entire fleet of 21 U.S. KMs. This raised the pipe opening above roof level and exposed the 'butterfly' flaps to view. The modification was made to SP 9010 and siblings 9011-9017 on the production line.

The taller pipes were soon retrofitted to 9003-9009 and the six Prototypes by SP. Photography of SP 9010's delivery confirms that this change was in place from new.

Low

position, 9003-9009

Krauss-Maffei

AG

|

Raised

position, 9010-9017

Howard

P. Wise

|

SNOW PLOW WITH 'FACTORY DENTS'

Fleetwise, this mod lies somewhere between a KM pre-delivery change and an SP post-delivery modification. But since in 9010's case it was a pre-delivery change on the shop floor, we're listing it here.

We thought for months that SP 9010's snow plow pilot had been dented in the lower center. The 'defect' appeared as early as October of 1964.

Richard

Oed Collection

|

That pilot no longer exists, having been removed when 9010 was converted to Camera Car. But closer study of the issue showed a very similar 'dent' in the rear plow. What was going on? What were these KMs hitting? Since we were going to remove that plow and mount it on the front, some deep photo research was in order.

The results were surprising. The first two units off the production line, "Nr.1" and "Nr.2" (SP 9003 and 9004) were used for extensive testing in Germany. Their plows were constructed with a smooth radius and a resulting peak at the bottom center of the plow.

SP9004

Krauss-Maffei Werkfoto |

SP9005

Krauss-Maffei Werkfoto |

Apparently there was an interference issue. We speculate either a pilot-to-pilot contact, something involving the 'glad hand' connectors on the air hoses, or some unique combination of both. Since the next mod was made in Germany, whatever must have been the cause would likely have revealed itself there, between these two units.

KM made a fix we call the "KM Clip". The peak was cut back slightly, and a triangle was fitted with crisp metalworking techniques. This is how all the first seven units (9003-9009, the First Batch) were shipped from KM.

SP9006

Krauss-Maffei Werkfoto |

But this was evidently not enough in practice. Almost as soon as the First Batch hit the rails, they began to be modified by the SP with this more severe cutback and a larger triangle, laid in with a very heavy weld bead. We call this the "SP Clip".

SP9010

Collection

|

SP9010

Collection

|

And research showed that every one of the First Batch eventually received this SP modification. But what of our 'dents'?

More research - including films of 9010 swinging off the deck of the ms Birkenfels at Houston - showed that 9010 came factory-equipped with this 'defect'. As did every one of the eight units (9010 to 9017) of the 'Second Batch'.

SP9010

Collection

|

Southern Pacific discovered that the "KM Clip" wasn't enough and began applying the "SP Clip" during the same months that the units of the Second Batch were still on the line in final stages of completion. Either at SP's suggestion, or in a method devised by KM, the plows were converted from smooth peak to what looks like an impact-formed recess, bypassing the "KM Clip" procedure completely.

Richard

G. Oed Collection

|

Howard

P. Wise

|

Another modification, hiding in plain sight. SP 9010 is being restored with this 'defect' repaired - we're taking the dents out of the dent, but keeping the dent! (See "Front End" under "Restoration Progress")

BULLSEYE' SIGHT GLASSES

The original-style radiator sight glasses were of similar style to the fuel tank and intermediate gear box 'bullseye' design. The bright natural brass-bronze was attractive, but a single spot on one side and double spots on the reverse did not allow viewing in backlit circumstances, nor equal viewing from front or rear.

The replacements corrected this shortcoming.

The glasses were apparently in developmental transition at the time of the First Batch delivery. Units 9003, 9005, 9008 and 9009 departed with no sight glasses installed. A later design (with a vertical glass allowing better visibility of water levels) was fitted to all units of the second delivery batch, and retrofitted to all units of the First Batch. Units 9003 and 9007 operated with no replacements for some time and unit 9008 ran with only a partial set. There may have been others, but this is what has been documented so far.

|

|

See "The Krauts Leaving Munich" for further details.

Early

style glass

Krauss-Maffei

AG

|

Krauss-Maffei

AG

|

Late

style glass

H

P Wise

|

Howard

P. Wise

|

THE SP MODIFICATIONS:

RAISED MULTIPLE-UNIT JUMPER BOXES - MID-1964

After a very short time in service, SP 9010 had its multiple unit jumper cable boxes raised by two-thirds the height of the box itself.

Original

Krauss-Maffei

AG

|

Modified

Howard

P. Wise

|

With several hundred EMD cab-style units in the SP locomotive pool, lashups with KMs were common. We believe that a disparity in connector box location between KM and F7 caused a short-cable problem with the older field loop dynamic brake connectors. The expedient solution in the Spring of 1964 seemed to be the removal of the entire field loop jumper box, as seen here on 9004 and 9007.

No possibility to connect, ergo, no problem -- for the time being, anyway!

John

Signor

|

John

Signor

|

Raising the KM's boxes appears to have been the permanent solution. SP 9010 retains its rear MU box in this raised location. A new front box has been fabricated and installed in the raised position to match our 'target appearance' date of October 1964, thus retaining SP 9010's very first SP 'field mod'.

Bob Zenk Photo

|

|

MU HOSE CONNECTIONS - MID 1964

This one evaded detection for over a year, and is what the SP 9010 restoration team likes to call 'hiding in plain sight', or more often, "INNT" - 'I Never Noticed That!'

The front pilot MU connections had been stripped when the PLA received former SP 8799 (9010). But early in its lifetime, apparently the correct lengths of MU hoses were unavailable to some shop (doubtful it was Sacramento or Roseville) and pipe extensions were introduced to the front hose bases on both sides.

SP

9010

Richard G. Oed Collection |

It remains to be determined whether this 'modification' - really more of a field improvisation - will be duplicated for SP 9010's restoration.

FUEL TANK SURGERY - MID-1964

There are three square flush-welded patches in SP 9010's fuel tank. These did not appear in films taken at delivery in May of 1964, but are evident in a photograph taken that same year in October.

This account comes from Carl-Peter Zander, KM's Project Lead in the USA 1965-68:

"Shortly after the delivery there was one locomotive which was always starving on fuel. We tried everything to detect the reason: changed fuel pumps, filters and check valves; nothing was wrong, but the engine did not get enough fuel. Something must have been wrong with the suction line, and therefore two holes were cut into the tank. The reason then was evident: accumulated dirt in front of the pipe."

We believe Peter is recalling our 9010. Here are photos of the patches:

Fireman's

side

Bob Zenk Photo

|

Bob Zenk Photo

|

Engineer's

side

Howard

P. Wise

|

Why three holes? It depends on what the 'dirt' was, especially if it was some kind of organic mass from biological fuel contamination. Or maybe the first hole that was cut didn't reveal the problem. Why only 9010? No answers at present.

REFLECTIVE STRIPING ON SANDBOXES - LATE 1964

Gordon

Glattenberg

|

This minor cosmetic change was likely applied to prevent crewmen from walking into the protruding side-mount traction sandboxes. It soon became a fleetwide addition, retained until the end of service.

Howard

P. Wise

|

SP 9010 had its sandboxes removed during conversion to Camera Car, and the areas were plated over by the SP (unfortunately for the restoration team). All eight boxes will be re-created and the Scotchlite will be applied, retaining SP Modification Number Two.

PLATFORM LIGHTS - 1964

These were added front and rear, over the center platform area. The front example was removed when ballast weights were added.

Richard

G. Oed Collection

|

SP

9010 Rear Light

Bob Zenk photo |

The rear platform light is intact and will be retained. The front installation had not yet appeared by our 'target restoration date' of October 1964. But one still may be installed for practicality, so wiring has been provided.

NOSE FRESH AIR VENTS - 1964-65

This modification also escaped detection until the restoration process demanded a closer look.

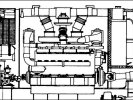

These pop-up vents are located on the short hood, and ventilate the air space in the compartment. Contained within are the forward Voith transmission and hydrodynamic brake. Both are sources of considerable heat. Both are also cooled by the heat exchanger-radiator arrays, and don't require ventilation. But the air space when heated affects the comfort in the cab, and so must be vented.

The German manufacturer Happich supplied these vents. They are used in large quantity on other German and KM locomotives. There is also a third identical vent on SP 9010, over the 'Water Closet'.

David

Thelen

|

Richard

G. Oed

|

Richard

G. Oed

|

Howard

P. Wise

|

When looking to install a pair of European-sourced replacement vents in the re-created short hood of SP 9010, we realized that photos taken at various times showed these vents opening in two different directions. As built they opened with the rear edge up, venting the air through through draft. As modified, they were turned around to face the slipstream and vent through force. SP 9010 received this mod some time in 1965, as did all other Series units.

Howard

P. Wise

|

Morris

Abowitz

|

Otto

Baumgartner

|

Further study revealed this as another SP modification. Our KM consultant, Carl-Peter Zander, recalled this mod as part of the SP's chain of efforts to cool the hot KM cabs. Since this modification post-dates our 'window' of October 1964 and because there is no longer a forward transmission to generate heat, 9010's new nose vents will be installed in the original trailing position.

RENUMBERING - 1965-66

The fleet renumbering that saw 9003-9017 become 9106-9120 (and which saw 9010 become 9113) took place 'officially' in late 1965. (A document entitled "Cross Reference Tabulations For Reclassifying and Renumbering of Locomotives", Project M-113 was dated November 18, 1965 and came from the Office Of System CMO in San Francisco under a cover letter dated the day before.)

It took some time for the renumbering paint 'patches' to be applied to all units. We have photos of 9010 still carrying its original number as late as April of 1966. These two rare shots show the memorable and characteristic 'patch' appearance of the KM physical renumbering process - made much more noticeable by the rapid deterioration of the glossy German enamel under relentless California sun and SP's harsh car-washing chemicals.

Carl-Peter

Zander Collection

|

SMU/DeGolyer

Library

|

LOWERED CAB WINDOWS AND VISOR - 1965

Two recently-shared photos -- one taken by Otto Baumgartner, a German KM technician working in Roseville, and one by photographer Jack Whitmeyer -- show that our own SP 9010 may have been the first experimental candidate for the most visually apparent KM fleet modification of all!

A visor was constructed for 9010's windshield from a single piece of sheet metal and what appears to be black vinyl 'pinch welt' upholstery trim. The one-piece visor takes a different shape than the later three-piece fleet application, and is clearly a 'trial run'.

Otto

Baumgartner

|

Otto's photo above shows a couple of concerned observers in March of 1965, as the late afternoon Roseville sun seems to be cooperating with the experiment. The chap on the right may be the Mechanical Department's Frank Kurz, SP's diesel-hydraulic project chief supervisor and the factory liaison with KM.

Below, the cab side windows were blocked with temporary 'blinds' from the same materials. In addition, the upper rear side windows of 9010 were experimentally painted with a dark green half-band. (Crews in the hot San Joaquin Valley sometimes taped sheets of newspaper over the insides to keep from frying!)

Jack

Whitmeyer

|

After taking 9010 over the 'Hill' to test the new blinders, and then sending it out into regular dispatch for more feedback, SP eventually developed a permanent solution to fit to the rest of the fleet -- though not all 15 units would receive the treatment.

Otto

Baumgartner

|

A three-piece aluminum sun visor (perhaps easier to fabricate and apply) was screwed to the overhanging windshield brow. The area of the sliding operator's windows was lowered nine and a half inches by welding in a steel plug and 'sectioning' the aluminum framework.

This has sometimes been reported as a KM factory 'kit' -- but the former KM employees we've talked to were adamant: this was an SP solution, and SP alone was welcome to take the 'credit'. (Why the heavy sheet metal solution was applied, and not some sort of semi-permanent interior shade, is open for conjecture. Water ingress may have been more of a factor here than sun.)

SMU/DeGolyer

Library

|

Howard

P. Wise

|

SP 9010 eventually received the 'standard' low window and visor and fully-painted-out rear glass -- and no, the paint didn't stick very well at all. The lower edge of the windshield was raised in 1969 to clear the boxy camera nose.

Ca.

State Railroad Museum

|

Ca.

State Railroad Museum

|

Ca.

State Railroad Museum

|

All window modifications were torched out during the uncompleted prior restoration attempt. Current plans for SP 9010 call for a return to the original large-window configuration -- complete with neutral gray locking strip trim, as soon as we figure out how to obtain or replicate a close facsimile!

The relatively mild year-round temperatures and scenic bounties of operation in Niles Canyon will certainly be kinder to the crew than was Sacramento or Bakersfield in the summer of the 1960's! We expect the view from 9010's comfy cab to be superb -- and very popular.

Bruce

R. Heard

|

CAB ROOF VENT WITH DEFLECTOR - 1966

The time frame for this modification isn't certain. This U.S. standard-issue Prime Manufacturing round vent may have been applied either before or in conjunction with the 'R7' shopping of 1966. The rounded deflector plate may be an acoustic block for air horn noise, or an air scoop, or both - we're unsure at present.

Howard

P. Wise

|

A curiosity exists on the roof of SP 9010 -- we discovered that the roof hatch was installed in a reversed position during the 1969 Camera Car conversion. This moved the vent to the opposite (left rear) corner of the hatch - a location faithfully recreated by one scale model manufacturer, but incorrect for any units except SP 8799, the Camera Car. (We say again: "INNT!")

The hatch will eventually be returned to the original factory location. The vent may be retained for practicality, but the deflector/scoop has already been removed, since its profile did not appear on SP 9010 in 1964.

(All modifications are being noted and photographed, and attempts to preserve removed pieces will be made.)

HOOD DOOR LOUVERS - 1966

These small appliqués on the 'L1' and 'R1' engine compartment doors appeared on eleven of the fifteen Series units.

Bob Zenk Photo

|

Bob Zenk Photo

|

We don't know what these vents were for, but our best guesses are (1) to assist cab interior cooling, and (2) to provide cool air to prevent forward turbocharger failures - a problem which deviled SP 9010, according to Otto Baumgartner's notes. (Could we be looking at another pilot program first applied to SP 9010?)

ROOFTOP HEAT EXCHANGERS - 1966

Also unclear is whether SP 9113 operated with these added components before the full 'R7' shopping in December of 1966. The photos show both visual possibilities -- though we lean towards the R7 as their first appearance on 9113.

If installed before radiator tank mods

SP

9109

Vic Reyna |

As installed after tank mods

SP 9113 Robert L. Hogan |

SP

9113

Robert L. Hogan |

We wondered about the function of these for some time. We got our answer from Carl-Peter Zander, former Project Leader for KM.

According to Peter, the coolers were to correct a problem with the constant-speed air compressor couplings, which shared hydraulic fluid with the transmissions. Burned fluid from leaky couplings caused frustrating transmission failures until the problem was isolated. (This must have been particularly troubling to transmission maker Voith AG, since the L 830 rU transmissions themselves operated almost without criticism, unlike many other components.)

SP 9010 shop notes from Otto Baumgartner show SP 9113 (9010) as having had both transmissions replaced in the 'big rebuild' of 1966, and a troublesome compressor coupling was replaced in 1967. According to Peter Zander, rooftop coolers were first installed on SP 9109, but appear to have been subsequently applied only to the four 'R7' candidates (including 9010)during the 1966-67 'modernizations'.

The heat exchanger elements and piping were removed when the unit was converted to Camera Car, but some footings and brackets remain (also 'faithfully' duplicated in scale by a model manufacturer). Capped pipe ends also remain on the hood tops, but precise pipe routing has not been determined, since the mechanical compartment housing the compressor and pumps was vacated in the conversion process, and no contiguous plumbing for this modification remains.

Howard

P. Wise

|

Howard

P. Wise

|

STUBBY MU DROP STEP - 1966.

SP 9010 lost its front MU drop step to the Camera Car conversion, and its rear one to a switching incident in the not-too-distant past. While researching the proper shape and configuration to fabricate two new steps, we discovered something interesting: All the beautifully rounded original steps were beat up and bashed, almost from the start.

And 9010 didn't escape, not even for her 'cover girl' appearance on Joe Strapac's SP Historic Diesels Volume 2!

Gordon

Glattenberg

|

The original steps were gently radiused, and that radius was the first to collide with... something. (The rubber-covered loop is the sling for MU jumper cables.)

David

Thelen

|

The SP's solution started appearing in 1966 or so, with an abbreviated and squarish front profile on replacements.

SP

9116

Tom Dill |

Turns out that not even the new pieces were immune:

SP

9117

David Lustig |

But what was bashing up the originals? We considered what the units would most likely be coupled to. And one potential culprit loomed largest: the buffer-equipped EMD F-7. (Again, the F-unit as culprit!)

Howard

P. Wise

|

Photographic comparisons advanced our theory, and measurements taken on the Museum's fleet seem to bear it out. It would probably take some pretty good slack, buff, jounce, and rebound to cause the bashing, but this seems the most promising theory, since the coupling of KMs to F-units was very, very common.

Meanwhile, we have adopted a strict 'no buffers' rule at PLA for the nice, new -- and slightly shorter -- drop steps we've made!

EXHAUST CENTERING APPLIANCES - 1966

When the exhaust pipes were raised above hood top level, some sort of unchecked oscillations were a consequence. These Rube Goldberg-like spring tower contraptions were created by SP to damp those motions and keep the pipe centered. (Click here to watch "kicking the pipe" video!!)

Howard

P. Wise

|

SP 9010 still has both sets of exhaust flaps and both sets of spring towers. The flaps will remain, naturally, but the towers will be removed as the unit is 'backdated' to 1964. The tower devices will be preserved and possibly displayed.

M3 AIR HORN - 1966

At the factory, all KM Series units were provided with what the drawings specified as a 'Nathan P14 - R 2/6' air horn. These were installed temporarily to low European clearances on select test and delivery units, then reconfigured and mounted in the standard rooftop location at setup in Houston.

Testing and delivery configuration --

9004-9006, 9016, 9017

Krauss-Maffei

AG

|

Final configuration -- SP 9010 and all

units

SMU/DeGolyer

Library

|

Our 9010 gets a sweeter voice.

From at least April of 1966 as SP 9010 (and for a yet-undetermined period as SP 9113) our artifact gave up its factory 'P3' Air Chime in favor of a crisper-sounding Nathan M-series. The M's visual spotting guides are the shorter-radiused flares of the horn ends, a deep casting on the diaphragm end, and the level mounting of all three horns across the bracket.

RD

McDonald Photo

|

SMU/DeGolyer

Library

|

SP 9113 reverted to the standard Nathan P-series, likely at the 'R7' shopping of December 1966.

SP 9010 carried the M3 for a only short time, and ended its career as SP 8799 'Camera Car' sporting the more common P3, mounted over a specially-constructed steel microphone enclosure.

Shade

Tree Books

|

SP 9010 will have its 'P14R2' re-created specially, since it's considered that the 'P3' was the sound most associated with SP KMs. But an M3 will also be available!

'R7' SHOPPING AND FINAL APPEARANCE CHANGE - 1966

In addition to internal modifications and general overhaul, four 'Series' units (9107, 9113, 9116, and 9120) received distinctive outward appearance changes over the Winter of 1966-67.

Dick Steinheimer understandably never considered the picture below to a prime candidate for publication, but through the accession of Dick's photo negatives by the DeGolyer Library at Southern Methodist University, we were able to access and share this now-noteworthy shot of SP 9113 at Tracy, California, just a short time before it received its final locomotive mods.

Dick

Steinheimer

SMU/DeGolyer Library |

SP 9113 (9010) was released from Sacramento General Shops on December 2, 1966, sporting the following visual modifications it would carry for the remainder of its locomotive life:

BALLAST (ADDED WEIGHT FOR TRACTION) - 1966

SP 9113 received added weight, likely during 1966 when being rebuilt in Sacramento General Shops. We have yet to see photos of the "unmodernized" 9113 with visible added weight. This weight varied among the Series units receiving this mod, but averaged between 7.5 and 9 tons.

PILOT DECK WEIGHTS

The most apparent location was over the pilot platform on the front ends. This ballast appears to be added using a standard SP method, employing solid billets of square-section bar stock, welding and bolting them into place. (Seen here on 9117, left, and 9120, right.)

David

Lustig Photo

|

Mike

Myers Collection

|

RAISING THE RAILINGS

The added volume of the weights raised the effective height of the platform walk area. Front handrails were raised on the affected units by simply raising the factory assemblies, adding angle iron support brackets to the center uprights, and a handrail tube extension on each side, as seen here on SP9117. (The crude M.U. cable hanger seen on the engineer's side "Y" stanchion was not installed on any units other than SP 9117, so far as we can tell.)

David

Lustig Photo

|

BATTERY BOX WEIGHTS AND BATTERY CHANGE

While tracing some of the fuel piping, we observed how SP added weight to the frame. Notice on the wall the ghost of an angle iron, like the rusty one you see at the rear of the box. Notice also the flat bar running left to right. The position of these flat bars and the angle iron define the size of the battery. There are two common sizes in this country, the difference being in the thickness (resulting in a difference in the AH capacity). The change in the placement of the angle iron and the cut flat bar mean that the locomotive was originally equipped with smaller, thinner batteries than those normally used by the SP.

Howard

P. Wise Photo

|

Howard

P. Wise Photo

|

Howard

P. Wise Photo

|

RADIATOR HEADER TANK ENLARGEMENT

The square shoulders -- so visually characteristic of the Series units' latter years -- were added to extend the capacity of the radiator cooling system. Sight glasses were moved to the engineer's side only, and staggered to obtain full 'coverage' of tank level. (No extra parts were required by consolidating the function to one side only.)

Richard

G. Oed Collection

|

SP 9010's square header tanks remained after conversion to 'Camera Car' SP 8799. The construction of the tanks will be fully documented, and the radiator hoods (still with these original Behr Kuehlsystem filler and access caps) will be restored to 1964 KM configuration.

Howard

P. Wise

|

Howard

P. Wise

|

STEP TINS FOR CENTER RADIATOR FAN ACCESS

David

Thelen Photo

|

SP 9010 had its 'step tins' (narrow footing platforms) removed when the radiator header tanks were enlarged and squared off. These were useful perches when raising the side-hinged center radiator fans for access to the cooling system. They will be reconstructed, as will the stand-off brackets for the radiator sight glasses also seen here.

MULTIPLE AXLE DRIVES

Whether for advanced wheelslip control or increased vigilance over axle gearbox failures, the R7 mods included the addition of GE axle generators on all six axles. They were applied on the engineer's side front and fireman's side rear, to allow for free exchange of trucks from front to rear, just as the factory intended.

SP

9120

Otto Baumgartner |

SP 9010 (as SP 9113) received the maximum complement of axle drives. As Camera Car SP 8799, some were relocated and some were removed.

RELOCATED HANDBRAKE

SP 9010 (as SP 9113) had its handbrake relocated to the right front, in common with its three 'R7' siblings. A lever-type stand was applied to the engineer's side front walkway, and two lower access panels were shortened at the hinges to clear the crank rod assemblies. A substantial chain roller, new brackets, and new linkages were created, and brake cylinder piping was slightly rerouted.

Otto

Baumgartner

|

Otto

Baumgartner

|

As 'Camera Car' SP 8799 the R7 handbrake location was eliminated by the camera nose, so a heavy brake stand was bolted outside the handrails on the fireman's side rear. That stand survives, but has been removed.

SP

Photo Zenk Collection

|

A temporary expedient was devised for SP 9010's move from Sacramento to Niles Canyon.

Bob Zenk Photo

|

A practical decision was made to not recreate the original chain-and-gears handbrake mechanism. But in order to maintain a correct 1964 frontal appearance, SP 8799's brake stand has been modified and relocated rearwards, taking advantage of a handrail stanchion's added strength to eliminate the ungainly-looking braces.

|

And finally...

There's one action of ownership that the SP performed immediately upon delivery, and which barely qualifies as a 'modification'. But it nonetheless represented the very first alteration of the factory KM appearance.

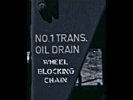

Stencil magic.

Spray-stencil lettering was applied in several locations on the locomotive by SP's painters -- to indicate frame-level compartments used for rerail frog storage, the emergency fuel cutoffs, a place to hang wheel blocking chains, and the location of the two fire extinguishers.

There was also a correction applied to at least a few units -- the fillers for engine cooling water and hopper (toilet) water were delivered crossed -- one hopes that this didn't lead to a mechanical breakdown, but it's certainly possible!

Based on a study of tonality in the photos, the SP stencils appear to be white paint, while the KM lettering appears to be SP Lettering and Striping Gray. (The end photo seems to show the reverse, but for some reason KM specified white for the end numbers, and the stencil paint here might simply be a bit thin.)

David

Thelen

|

David

Thelen

|

David

Thelen

|

David

Thelen

|

David

Thelen

|

David

Thelen

|

Cab customizing.

Inside the cab, the back wall was augmented with a large stencil for weight and class. (One can imagine the Germans wincing when they first saw this normal but crude SP practice applied to their pristine Jade Green enamel.)

The photo below shows all three layers of SP cab stenciling, from SP 9010 through SP 9113 to SP 8799, revealed by patient and methodical 'sandpaper archeology' through two layers of SP paint, down to the original KM finish.

Howard

P. Wise

|

Germany vs. USA

This new stenciling was done in U.S. style typeface with 'bridged' stencils. Naturally, no attempt was made to match the KM-applied DIN 1451 'Mittelschrift' typeface common to contemporary German locomotives -- and also used for German public signage.

And finally, the home service base (Roseville) was added in a small stencil below the cab side road numbers, and a 2" Scotchlite dot was applied above them, signifying that the unit is spark-arrested-by-turbocharger.

David

Thelen

|

Jack

Whitmeyer

|

Wrapping up: a chronicler's work is never done.

Every new or old photograph we study, and every time we climb on and around SP 9010, there's a chance we'll turn up a new detail or a fresh question. And when we discover new information in one new photo, and then return to study familiar ones, even more info surfaces -- as though it had been hiding in the shadows, waiting for yet another 9010 crew member to invoke the 'INNT' escape clause - "I Never Noticed That!"

Keep checking these pages, as the research and restoration of SP 9010 continues. And if you have original photo coverage or other rare information not seen elsewhere, we'd love to hear from you!

SP 9010, Traver, CA, August 1965

Jack

Whitmeyer

|